1. INDICATION FOR USE

The torque wrench is used for dental requirements in the area of dental surgery.

Any other form of use is ill advised and can be harmful.

This is an instrument with a precise system of torque control allowing the screwing of prosthetic parts at a definite torque.

2. AREA OF APPLICATION

The torque wrench must only be used by someone with dental experience, with knowledge in implantology as well as in prosthetic techniques related to dental implants for the application described here above, and in compliance with the provisions in effect in relation to the prevention of accidents at work, protection of employment, and the instructions for use.

In accordance with these provisions, the user must only use working instruments without defects, observe the principle of correct use, protect themselves and the patient or third party against any danger, and prevent all contamination by the product.

3. GENERAL SAFETY INFORMATION

Before use, check that the right-angle driver is not damaged and that no part of it is missing. Use protective gloves, glasses and a mask.

After insertion of the mandrel tip, check that it is correctly held, by a slight rotary movement. Do not handle the mandrel tip during operation.

It is recommended to the practitioner to test the torque wrench before using it on the patient in order to check that it is correctly functioning. In the event of visible malfunction or damage, immediately stop using the instrument and inform contact@conmetior.com.

4. TECHNICAL CHARACTERISTICS

The user is responsible for the appropriate choice of operating conditions, which will prevent any risk to the patient or to another person. All the torque values are indicated on the bottom of the driver. In choosing the torque, follow the recommendations of the implant manufacturer.

5. USING THE TORQUE WRENCH

The right angle driver is supplied unlubricated and unsterilized. It is important to do this yourself before first use, and also check that the torque wrench is not damaged and no part of it is missing.

5.1 CONNECTING AND DISCONNECTING THE MANDREL TIP

The use of protective gloves is recommended each time the tool is handled. Check the condition of the mandrel tip to be used and handle it properly and carefully.

Inspect the latch regularly to ensure that it is properly fixed. Check that the mandrel tip is properly attached, through a slight axial movement on each tool change.

Remove the mandrel tip by opening the latch and pulling outwards at the same time.

5.2 TORQUE SELECTION

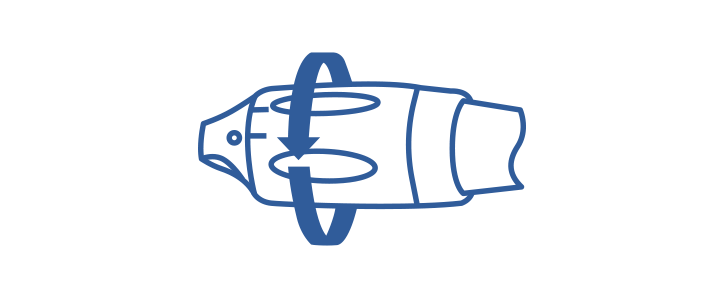

While holding driver handle, turn the black knob at the bottom of the wrench in the direction of the arrow.

The torque values are indicated on the instrument.

The implant manufacturer’s recommendations are to be followed when choosing the torque.

5.3 SCREWING AND UNSCREWING

Maintain the torque wrench in one hand. Turn the handle toward the “screw” direction until an audible click is heard, indicating that declutching has taken place and that the selected torque has been attained.

Going in the opposite direction, “unscrew” will loosen the screw.

6. HYGIENE AND MAINTENANCE

The re-sterilization of reusable medical devices must be performed by a properly trained and protected member of staff.

The re-sterilization protocol must consider the risk of infection. Refer to the manufacturer’s instructions for each product used.

Particular care to adhere to the instructions regarding concentrations, lengths of exposure, the replacement of solutions, and the lifespan of the products.

Never combine products and adhere to the guidelines regarding the disposal of used products.

Wear suitable protective clothing.

Never immerse the torque wrench in any kind of solution.

Never clean the torque wrench in an ultrasonic tank.

Clean the device immediately after an operation.

Use only detergent or disinfectant solutions with a neutral or slightly alkaline PH.

It is extremely unadvisable to use products which may fix X proteins to the unit (e.g. alcohol, aldehydes...).

Do not use sodium hypochlorite (bleach) as there is a high risk of corrosion.

6.1 EXTERNAL CLEANING

The torque wrench can be cleaned by using a brush under tap water.

External disinfection using a spray, or a wipe soaked with disinfectant products microbiologically controlled (ph. between 2.5-9). In any case, it is important to follow the reaction time of the disinfectant product used.

6.2 LUBRICATION

When using for the first time and prior to each sterilization, lubrication is to be carried out using a spray can.

Keep away from any source of heat or ignition.

Wear a protective face mask. Place a turbine-type nozzle on the spray can. Place the spray can nozzle into the hole at the bottom of the driver marked “oil.”

Maintain the spray can nozzle against the torque wrench until the pressure drops again. Vaporize 1 to 2 seconds. The oil passes over the entire instrument, acting as a cleanser and a lubricant.

STERILIZATION

Read the instruction leaflet provided by the sterilizer manufacturer.

Adhere to the space specified between pouches and do not overload the sterilizer.

Only sterilize instruments which have previously been disinfected, cleaned, lubricated, and tested.

Remove the rotating instrument from the torque wrench prior to sterilization.

Make sure that the device does not have any areas of corrosion or cracks, and check that it is operating properly.

Ensure that the product is dry; if necessary, dry any residual water with medical quality pressurized air.

Use sterilization pouches suitable for the torque wrench and the sterilizer. Always use one single torque wrench per pouch.

In order to prevent any retention of water, place the pouch in the sterilizer in such a way that any concave parts are face down.

If the sterilizer has several types of cycles, choose a cycle designed for medical devices (a minimum of 135°C at 2.13 bars (275°F at 30.88 psi) for 18 minutes.)

After each sterilization cycle, check that there is no water remaining on the inside and outside of the packaging. Make sure that the flow indicator has changed to the correct color.

Keep the devices in the sterilization pouches away from light, moisture, and any kind of contamination.

Follow the manufacturer’s recommendations as seen on the packaging. The duration for which the device is kept after sterilization should not exceed 1 month. Label the devices, specifying the expiration date. After the expiration date, repeat the cleaning and sterilization procedure.

GUARANTEES

If you think you have received a product in poor condition or if you think the packaging has been tampered with or damaged before delivery, please refuse to accept the package and return it to the delivery person.

Email us at contact@conmetior.com mentioning your order ID. We will personally ensure that a brand-new replacement is issued to you with no additional cost.

Make sure that the ORIGINAL PRODUCT TAG is present when you send back the product.

You must return any goods within 10 days of date of receipt.

Due to Federal regulations, apart from condition reserved herein above all sales for any of our products are FINAL and NON-REFUNDABLE.

This Right-Angle Driver is guaranteed against all manufacturing defects for 6 months from the date of invoice. This guarantee does not apply to wear and tear parts.

All changes or additions to the product without the express agreement of Conmetior render this guarantee null and void.

The guarantee becomes null and void if the technical instructions are not followed.

Conmetior cannot be held responsible for damage resulting from or which could result from normal wear, use, cleaning or incorrect maintenance, the non-observance of instructions for use or connection, scaling or corrosion, impurities in the water supply system or unusual chemical or electrical influences or non-observance of the instructions, maintenance instructions and assembly of Conmetior and other manufacturer’s instructions.

Delivery charges incurred when sending an instrument back to Conmetior for repair will be paid by the client, even if the repair itself is covered by the guarantee.

Postage and packaging fees when returning the instrument to the client are covered by the guarantee.

So that guarantee requests are taken into consideration, please attach a copy of the invoice or a copy of the delivery slip.

Compatibility Chart

The chart is organized by implant company.

| IMPLANT COMPANIES | COUNTRY | DRIVER TYPE | Compatible Universal Prosthetic Kit | Compatible with Right Angle Driver |

|---|---|---|---|---|

| AB Dental Implant | ISRAEL | 0.055"-1.4mm | Yes | Yes |

| ACE Internal Hex implants | USA | 0.050"-1.25mm | Yes | Yes |

| ACE Octagon Implants | USA | Star-grip | Yes | Yes |

| ACE Tri-Lob Implants | USA | Unigrip | Yes | Yes |

| ADIN-IMPLANTS | ISRAEL | 0.050"-1.27mm | Yes | Yes |

| AIDI Biomedical | USA | 0.050"-1.25mm | Yes | Yes |

| Alfa-Gate | ISRAEL | 0.050"-1.25mm | Yes | Yes |

| Alpha Bio Implant Inc | ISRAEL | 0.060"-1.5mm | No | No |

| Alphadent Bio HPIDK | GERMANY | 0.090"-2.35mm | No | No |

| Alphadent IDK | GERMANY | 0.120"-3.0mm | No | No |

| American Dental Implant Corporation | USA | 0.050"-1.25mm | Yes | Yes |

| ANTHOGYR | FRANCE | 0.047"-1.19mm | Yes | Yes |

| ARDS Implant | ISRAEL | 0.050"-1.25mm | Yes | Yes |

| Argon | GERMANY | 0.047"-1.2mm | Yes | Yes |

| Astra Tech | SWEDEN | 0.050"-1.25mm | Yes | Yes |

| Aurosan Dental | GERMANY | 0.050"-1.25mm | Yes | Yes |

| Bego GmbH | GERMANY | 0.050"-1.25mm | Yes | Yes |

| Bio Implants Standard Plateform | GERMANY | 0.083"-2.1mm | No | No |

| Bio Implants Wide Plateform | GERMANY | 0.098"-2.5mm | No | No |

| Biodenta | SWISS | 0.047"-1.2mm | Yes | Yes |

| BioHorizons | USA | 0.050"-1.25mm | Yes | Yes |

| Bioline | ISRAEL | 0.048"-1.22mm | Yes | Yes |

| Biotech Dental | FRANCE | 0.047"-1.2mm | Yes | Yes |

| BlueSkyBio Conus 12 & Three | KOREA/USA | 0.050"-1.25mm | Yes | Yes |

| BlueSkyBio Internal Hex & Molar | KOREA/USA | 0.050"-1.25mm | Yes | Yes |

| BlueSkyBio Max | KOREA/USA | 0.048"-1.22mm | Yes | Yes |

| BlueSkyBio One Stage | KOREA/USA | Star &0.048"-1.22mm | Yes | Yes |

| BlueSkyBio Quatro | KOREA/USA | Star/Torx | Yes | Yes |

| BlueSkyBio Trilobe | KOREA/USA | Unigrip & 0.048" | Yes | Yes |

| Bone System Implant | ITALY | 0.050"-1.27mm | Yes | Yes |

| Bone System Implant | ITALY | 0.059"-1.5mm | No | No |

| Branemark | SWEDEN | Unigrip | Yes | Yes |

| Bredent Implant GmbH | GERMANY | 0.035"-0.9mm | Yes | Yes |

| BTI Biotechnology Institute, S.L. | SPAIN | 0.048"-1.22mm | Yes | Yes |

| Btlock s.r.l. | ITALY | 0.050"-1.25mm | Yes | Yes |

| Camlog Group | SWISS | 0.050"-1.25mm | Yes | Yes |

| Conmet | RUSSIA | 0.049"-1.25mm | Yes | Yes |

| Conmet (prior to 2020) | RUSSIA | 1.0mm square | No | No |

| Cortex | ISRAEL | 0.050"-1.25mm | Yes | Yes |

| Cowell Medi | SOUTH KOREA | 0.048"-1.22mm | Yes | Yes |

| Cumdent | GERMANY | 0.051"-1.3mm | Yes | Yes |

| Dental Ratio Systems GmbH | GERMANY | Star/Torx | Yes | Yes |

| Dental Tech | ITALY | 0.050"-1.25mm | Yes | Yes |

| Dentis Cleanlant s-CleanSystem | SOUTH KOREA | 0.047"-1.2mm | Yes | Yes |

| Dentis Cleanlant s-CleanSystem | SOUTH KOREA | 0.059"-1.5mm | No | Yes |

| Dentis OneQ Implant System | SOUTH KOREA | 0.049"-1.25mm | Yes | Yes |

| Dentis SQ Implant System | SOUTH KOREA | 0.049"-1.25mm | Yes | Yes |

| Dentium | SOUTH KOREA | 0.050"-1.25mm | Yes | Yes |

| Dentsply Ankylos | GERMANY | 0.039"-1.0mm | Yes | Yes |

| Dentsply Friadent Ceramed Inc, USA / Friadent GmbH | GERMANY | 0.048"-1.22mm | Yes | Yes |

| Dio | SOUTH KOREA | 0.035"-0.9mm | Yes | Yes |

| Dio | SOUTH KOREA | 0.047"-1.2mm | Yes | Yes |

| Dio | SOUTH KOREA | Torx | Yes | Yes |

| Ditron Dental | ISRAEL | 0.050"-1.25mm | Yes | Yes |

| Dr Ihde Dental, GmbH | GERMANY | 0.050"-1.25mm | Yes | Yes |

| Drive Implants | FRANCE | 0.047"-1.2mm | Yes | Yes |

| DSP Biomedical | BRAZIL | 0.035"-0.9mm | Yes | Yes |

| DSP Biomedical | BRAZIL | 0.047"-1.2mm | Yes | Yes |

| DSP Biomedical | BRAZIL | 0.051"-1.3mm | No | No |

| Dyna Dental Engineering | HOLLAND | 0.098"-2.5mm | No | No |

| Easyimplant | FRANCE | 0.047"-1.2mm | Yes | Yes |

| Eckermann Laboratorium | SPAIN | 0.050"-1.25mm | Yes | Yes |

| Fair implant | GERMANY | 0.059"-1.5mm | No | No |

| General Implants | GERMANY | 0.047"-1.2mm | Yes | No |

| Generic Implant | FRANCE | 0.047"-1.2mm | Yes | No |

| Generic Implant | FRANCE | Unigrip | Yes | Yes |

| Glidedentalimplant Hahn | USA | Unigrip | Yes | No |

| GlobalD 3.0 Implant | FRANCE | 0.047"-1.2mm | Yes | Yes |

| GlobalD EVL | FRANCE | 0.047"-1.2mm | Yes | Yes |

| GlobalD In-Kone | FRANCE | 0.047"-1.2mm | Yes | Yes |

| GlobalD TwinKone | FRANCE | 0.047"-1.2mm | Yes | Yes |

| GlobalD TwinKone4 | FRANCE | 0.047"-1.2mm | Yes | Yes |

| GMI Avantguard | SPAIN | 0.048"-1.22mm | Yes | Yes |

| GMI Frontier | SPAIN | 0.048"-1.22mm | Yes | Yes |

| GMI Monolith | SPAIN | 0.048"-1.22mm | No | Yes |

| GMI Phoenix | SPAIN | 0.031"-0.80mm | No | Yes |

| GMI Phoenix | SPAIN | 0.048"-1.22mm | Yes | Yes |

| Gunter Medical | GERMANY | 0.047"-1.2mm | Yes | Yes |

| Hi-Tec Implants | ISRAEL | 0.050"-1.25mm | Yes | Yes |

| Hiossen/Osstem Comp. Ltd | SOUTH KOREA | 0.048"-1.22mm | Yes | No |

| IDI 4041 | FRANCE | 0.050"-1.25mm | Yes | No |

| IDI 4051 | FRANCE | 0.046"-1.17mm | No | No |

| Impladent Ltd | USA | 0.050"-1.25mm | Yes | No |

| Implant Direct | USA | 0.050"-1.25mm | Yes | No |

| Implant Logistics | SPAIN | 0.050"-1.25mm | No | No |

| Implant Microdent System | SPAIN | 0.063"-1.60mm | No | Yes |

| Implant Vel | ARGENTINA | 0.050"-1.25mm | Yes | Yes |

| Imtec Corporation | USA | 0.050"-1.25mm | Yes | Yes |

| Innova LifeSciences Co, (Sybron Dental from 2006) | CANADA | 0.050"-1.25mm | No | No |

| Intra-Lock System International | USA | 0.050"-1.25mm | No | No |

| IQ Implant | ISRAEL | 0.050"-1.25mm | Yes | No |

| JDentalcare | ITALY | 0.095"-2.42mm | No | No |

| KAT Implant | USA | Square | No | No |

| Keystone/Lifecore Genesis & Prima | USA | Square | No | No |

| Keystone/Lifecore Renova | USA | 0.048"-1.22mm | Yes | No |

| Keystone/Lifecore Restore | USA | 0.048"-1.22mm | Yes | No |

| Klockner Implants | SPAIN | Star tork | Yes | No |

| Lasak Ltd | CZECHIA | 0.050"-1.25mm | No | No |

| Medentis (for all abutments screws) | GERMANY | 0.055"-1.4mm | No | No |

| Medentis (ICX-Hexagon instrument) | GERMANY | 0.047"-1.2mm | Yes | No |

| Medentis (t-ecco femaleinner part and ICX-mini cover screw) | GERMANY | 0.035"-0.9mm | No | No |

| Medical Instinct | GERMANY | 0.047"-1.2mm | Yes | No |

| MegaGen | SOUTH KOREA | 0.048"-1.22mm | Yes | No |

| MIS (Medical Implant System) | ISRAEL | 0.050"-1.25mm | Yes | Yes |

| MSI | FRANCE | 0.049"-1.25mm | Yes | Yes |

| Nanoplant Hochst | GERMANY | 0.050"-1.25mm | Yes | Yes |

| NDI Medical | GERMANY | 0.055"-1.4mm | Yes | Yes |

| Neobiotech Comp. Ltd | SOUTH KOREA | 0.048"-1.22mm | Yes | Yes |

| Neobiotech Comp. Ltd | SOUTH KOREA | 0.050"-1.25mm | Yes | Yes |

| Neodent CM (everything else) | BRAZIL | 0.047"-1.2mm | Yes | Yes |

| Neodent CM final abutment | BRAZIL | 0.035"-0.9mm | Yes | Yes |

| Neodent GM | BRAZIL | 0.055"-1.4mm | Yes | Yes |

| Neoss | U.K | Unigrip | No | No |

| Nobel/Branemark | SWEDEN | Unigrip | Yes | Yes |

| Noris Medical | ISRAEL | Unigrip | Yes | Yes |

| OCO BIOMEDICAL Biomedical | USA | 0.050"-1.25mm | Yes | Yes |

| Odontit S.A | ARGENTINA | 0.047"-1.2mm | Yes | Yes |

| OEM Dental Implants | HOLLAND | unigrip. not for Nobel | No | No |

| Oral implant S.r.l | ITALY | 0.050"-1.25mm | Yes | Yes |

| Paltop | ISRAEL | 0.050"-1.25mm | Yes | Yes |

| Paltop | USA | 0.050"-1.25mm | Yes | No |

| Radix | GERMANY | 0.050"-1.25mm | Yes | Yes |

| Ritter Implants | GERMANY | 0.051"-1.29mm | Yes | Yes |

| Sistema De Implante Nacional | BRAZIL | 0.035"-0.9mm | Yes | No |

| Sistema De Implante Nacional | BRAZIL | 0.047"-1.2mm | Yes | Yes |

| Sistema De Implante Nacional | BRAZIL | 0.051"-1.3mm | No | Yes |

| Southern Implant External | SOUTH AFRICA | 0.048"-1.22mm | Yes | Yes |

| Southern Implant Octa | SOUTH AFRICA | Star/Torx | Yes | Yes |

| Southern Implant Tri Nex | SOUTH AFRICA | Unigrip | Yes | Yes |

| Sterngold Implamed Dental Implant Systems | USA | 0.039"- 1.0 mm | Yes | Yes |

| Sterngold Implamed Dental Implant Systems | USA | 0.048"-1.22mm | Yes | Yes |

| Sterngold Implamed Dental Implant Systems | USA | 0.050"-1.25mm | Yes | Yes |

| Sterngold Implamed Dental Implant Systems | USA | 0.080"-2.0mm | No | Yes |

| Straumann | SWISS | Star/Torx | Yes | Yes |

| Sweden&Martina SPA | ITALY | 0.050"-1.25mm | Yes | No |

| Sybron | USA | 0.067"-1.7mm | No | Yes |

| T.B.R Group | FRANCE | 0.042"-1.09 mm | Yes | Yes |

| TFI System | ITALY | 0.050"-1.25mm | Yes | Yes |

| Thommen Medical | SWISS | Four Lobe | Yes | Yes |

| TOV Implants | ISRAEL | 0.083"-2.1mm | No | Yes |

| TRI dental Implants | SWISS | 0.050"-1.25mm | Yes | Yes |

| Victory | FRANCE | 0.035"-0.9mm | Yes | Yes |

| Victory | FRANCE | 0.047"-1.2mm | Yes | Yes |

| Zimmer Dental | USA | 0.050"-1.25mm | Yes | yes |